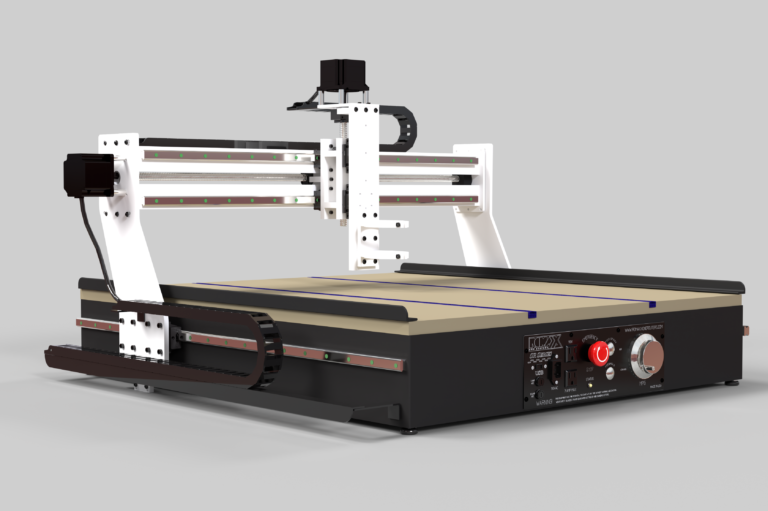

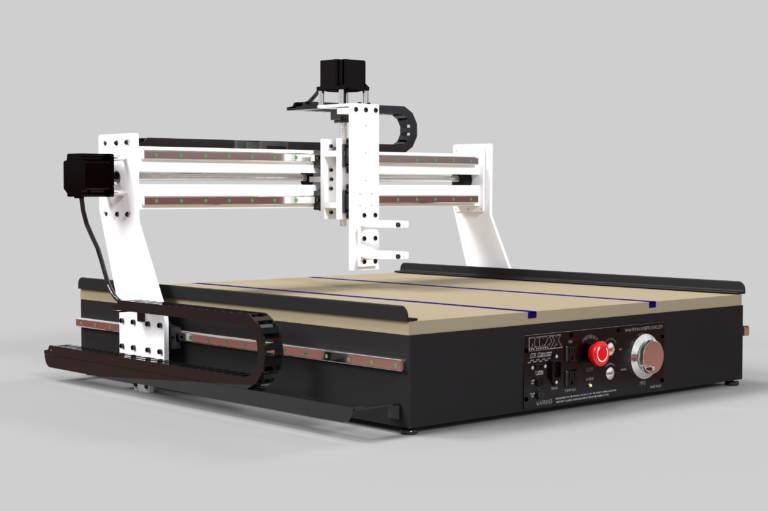

We are proud to introduce our SR line of CNC router machines!

Below you can find important specifications about the SR-1 Router.

Specifications:

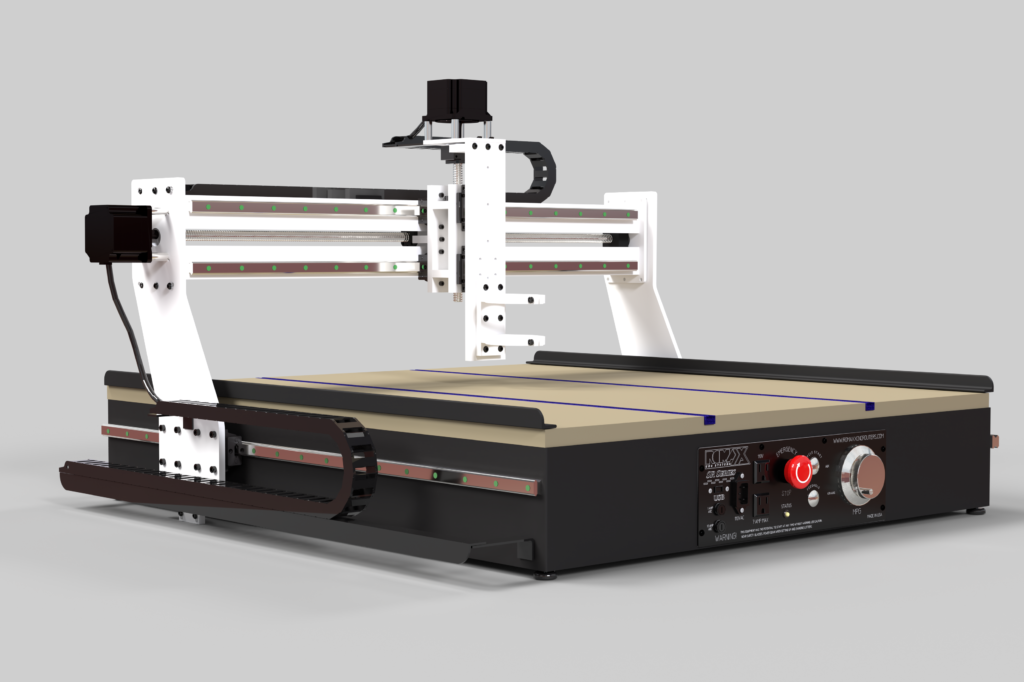

T-track Table dimensions: 37 X 41.5″ Two Incra style clamps included

Work Envelope

X axis: 35″

Y axis: 35″ (twin ballscrew setup clocked mechanically)

Z axis: 6″

Height Under Bridge: 8″ (with table)

Overall Dimensions

Width: 46 Length: 45 Height: 35 max. 29″ min.

Miscellaneous

Weight: 205 lbs.

Voltage: 120 VAC (220 VAC on request)

Why Buy a Romaxx SR Series Machine?

-It’s built in the USA, not simply imported and assembled here. We manufacture nearly every piece of this machine except the way system and ballscrews. Ballscrews are the industry standard for CNC machines. Have a look at any industrial CNC machine, it will have precision ground ballscrews. The SR-1 is a new machine design that we just released, it is a far improved design with added rigidity and higher grade components. The machine is strongly built from 1018 Steel and 6061-T6 aircraft grade aluminum exclusively.

-We’ve been in the CNC machine business for 20 years, first doing large machine retrofits and then moving to CNC routers around 2007, we have a lot of experience, in what works and what our customers need. We are machinists by trade. Our machines are in several schools and universities, businesses, home shops all over the world, NASA, there is even one on a NAVY sub!

-Our machines arrive fully assembled and ready to run right out of the crate. This is a large consideration, as some machines around the web arrive as a box of parts and a set of instructions.

-We stand behind what we sell and provide excellent customer support if needed. Many machines around the web are sold by importers/resellers, they know very little about them and parts are nearly impossible to get. If you need help we are just an email or phone call away.

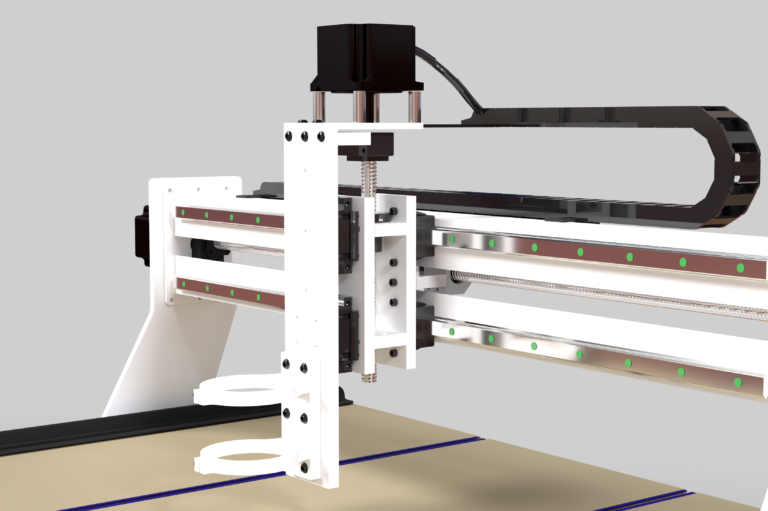

-We use hardened and precision ground THK style rail systems with dust seals

-We use hardened and precision ground sealed ballscrews on all three axis.

-We use two ballscrews on the long Y axis clocked together mechanically inside the machine. Each ballscrew drives one side of the gantry. The advantages are the gantry cannot rack on the base which will happen on machines that use only one ballscrew down the center or one side of the machine. Also there is no motor slaving setup where two motors are used, one to drive each side of the gantry, it’s nearly impossible to keep the machine square and if one motor quits, it can twist the gantry and damage the machine. Our dual screw clocked setup has proven reliable for many years.

-Our electronics are very generic, no proprietary boards or cables, everything is available from numerous sources.

-Our electronic panel on the SR-1 is housed in the base. This means no remote electronics “box” that sits off to the side of the machine with wires running all over. How the SR-1 CNC router looks in the picture above is how it looks all set up, just a power cable and communication cable to the PC connected to the front. There are no cooling fans on our electronics as they are not needed, in a wood shop, cooling fans are very troublesome with clogged filters etc. The front panel has two software controlled 120vac receptacles (7 amps max), to control spindles off and on, etc. With the added MPG which is an electronic handwheel, and makes setting up jobs much easier.

Click on the BUY NOW to go to the page to configure your SR-1 with spindles and accessories the way you want it.